## Introduction: Empowering Customer Decision-Making

Successful log cabin log cabin reselling businesss recognize that customer education directly correlates with sales conversion, customer satisfaction, and referral generation. Research indicates that buyers who receive comprehensive planning frameworks make purchase decisions 40% faster and demonstrate 32% higher satisfaction scores compared to those navigating the process independently.

This guide provides dealers with a complete customer education framework, enabling your sales team to position themselves as trusted advisors rather than transactional vendors—a differentiation that commands premium pricing and builds long-term customer relationships.

## Phase 1: Needs Assessment and Use Case Definition

### Primary Use Categories

Helping customers clearly define their intended use establishes the foundation for appropriate product selection. The four primary use categories require distinctly different specifications:

**Permanent Residence:** Year-round occupancy demands 92-140mm wall thickness, comprehensive insulation packages, engineered foundations, and full building code compliance. Investment range: €35,000-85,000 for 60-120m² structures.

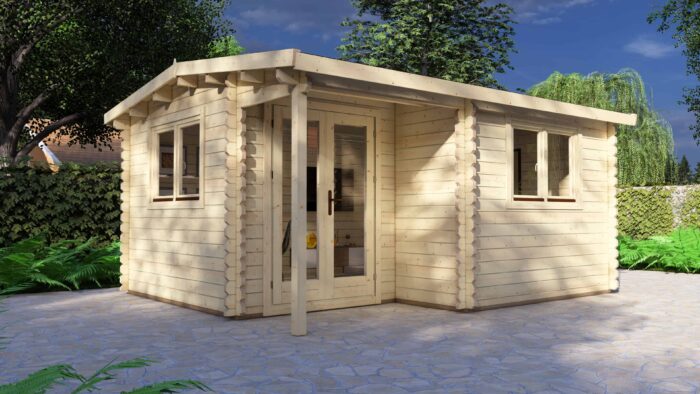

**Vacation Home:** Seasonal occupancy typically utilizes 70-92mm walls with moderate insulation. Three-season use is common, with heating systems ranging from wood stoves to electric radiators. Investment: €25,000-55,000 for 50-90m².

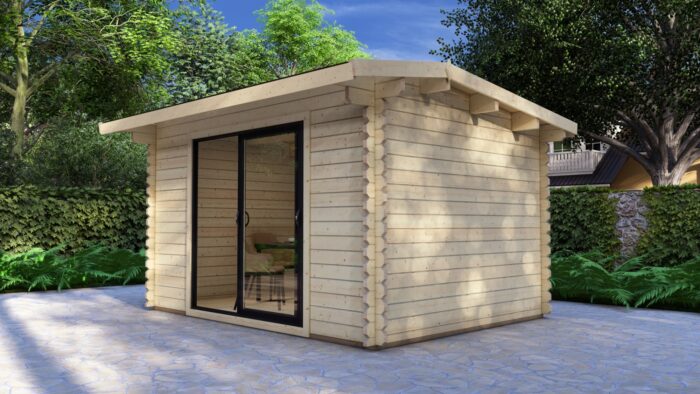

**garden offices/Studio:** Professional workspace requirements include sound insulation, reliable electrical systems, and climate control for equipment protection. 44-70mm walls suffice for most climates when properly insulated. Investment: €8,000-25,000 for 15-35m².

**Garden Storage/Workshop:** Functional spaces prioritize weather protection and security over thermal performance. 28-44mm walls meet most storage needs. Investment: €3,500-15,000 for 10-30m².

### Usage Pattern Assessment

Understanding frequency and seasonality optimizes specification selection:

– **Daily Year-Round Use:** Maximum thermal performance, durable finishes, comprehensive weatherproofing

– **Weekend/Vacation Use:** Balanced performance and cost, easy maintenance, security features

– **Occasional Seasonal Use:** Cost-effective solutions, weather resistance, minimal maintenance requirements

Dealers should use this framework to guide specification discussions, preventing both over-specification (wasted investment) and under-specification (poor performance and satisfaction).

## Phase 2: Site Assessment and Preparation Requirements

### Location Evaluation Checklist

Site conditions fundamentally impact construction feasibility, costs, and performance. Dealers providing comprehensive site evaluation guidance prevent post-purchase complications:

**Access Requirements:**

– Delivery vehicle access (minimum 3.5m width, firm ground)

– Crane access for large structures (4-6m clearance)

– Material staging area (20-30m² minimum)

– Assembly workspace around building footprint

**Ground Conditions:**

– Slope assessment (<10% ideal, >15% requires extensive foundation work)

– Drainage evaluation (avoid natural water collection points)

– Soil bearing capacity (minimum 100 kN/m² for standard foundations)

– Underground utilities location and clearance

**Regulatory Environment:**

– Building permit requirements (vary by municipality and size)

– Setback distances from property boundaries (typically 3-5m)

– Height restrictions (often 2.5-4m for unpermitted structures)

– Utility connection regulations and costs

### Foundation Specification Guide

Foundation selection represents 15-25% of total project cost and significantly impacts longevity:

**Concrete Slab Foundation:** Optimal for permanent structures, provides thermal mass, enables underfloor heating. Cost: €80-120/m². Best for level sites with good drainage.

**Strip/Perimeter Foundation:** Traditional approach for larger cabins, excellent load distribution, allows raised floor construction. Cost: €95-140/m². Suitable for varied terrain.

**Post/Pier Foundation:** Cost-effective for smaller structures and uneven terrain, good drainage, allows natural air circulation. Cost: €40-70/m². Ideal for non-permanent structures.

**Screw Pile Foundation:** Modern solution for challenging sites, minimal site disturbance, reversible installation. Cost: €110-160/m². Excellent for environmentally sensitive areas.

## Phase 3: Construction Specification Selection

### Wall Thickness Decision Framework

Wall thickness selection balances thermal performance, structural integrity, and investment:

**28-34mm (Single Layer):** Garden sheds, basic storage, tools/equipment. R-value ~1.0-1.2. Suitable for unheated spaces. Price range: €3,000-8,000 for 12-20m².

**44mm (Standard Garden Buildings):** Workshops, hobby spaces, occasional guest accommodation. R-value ~1.5-1.8. Basic insulation recommended for comfort. Price: €6,000-15,000 for 15-30m².

**70mm (Residential Garden Rooms):** Home offices, studios, gyms, three-season spaces. R-value ~2.3-2.6. Insulation package essential for year-round comfort. Price: €12,000-28,000 for 20-40m².

**92mm (Year-Round Residential):** Full-time occupation, vacation homes, rental properties. R-value ~3.0-3.4. Comprehensive insulation, double glazing standard. Price: €25,000-55,000 for 50-90m².

**140mm (Premium Residential):** Passive house standards possible, extreme climate suitability, maximum energy efficiency. R-value ~4.5-5.2. Price: €40,000-85,000 for 60-120m².

### Roof Construction Options

Roof specification impacts aesthetics, functionality, and maintenance:

**Flat Roof (5-10° pitch):** Modern aesthetic, usable roof space potential, lower material costs. Requires excellent waterproofing (EPDM or bitumen). Best for contemporary designs and garden rooms.

**Low Pitch (15-25°):** Traditional log cabin appearance, good water runoff, straightforward construction. Shingle or metal roofing. Versatile option for most applications.

**Standard Pitch (30-45°):** Maximum water shedding, creates usable loft space, traditional residential appearance. All roofing materials suitable. Ideal for residential structures.

### Window and Door Quality Tiers

Glazing significantly impacts thermal performance and initial cost:

**Single Glazing:** Basic weather protection, minimal insulation (U-value ~5.0). Only suitable for unheated storage or summer houses. Lowest cost option.

**Double Glazing:** Standard for residential use, good thermal performance (U-value 1.8-2.8). Essential for occupied spaces. Moderate price premium (15-25% over single).

**Triple Glazing:** Premium energy efficiency (U-value 0.8-1.2), ideal for permanent residences in cold climates. Premium pricing (40-60% over double glazing).

## Phase 4: Budget Planning and Total Cost of Ownership

### Complete Project Cost Breakdown

Dealer transparency on complete costs builds trust and prevents budget surprises:

**Log Cabin Package (40-45%):** Structure, windows, doors, standard roofing

**Foundation/Base (15-20%):** Ground preparation, concrete/posts, damp-proofing

**Assembly Labor (12-18%):** Professional installation if not DIY

**Electrical/Plumbing (8-12%):** Systems installation, fixtures, connections

**Insulation/Finishing (10-15%):** Floor insulation, wall insulation, interior finishes

**Exterior Treatment (3-5%):** Stain/paint, weatherproofing, UV protection

**Permits/Engineering (2-5%):** Building permits, structural calculations if required

Example: €25,000 cabin package typically requires €35,000-42,000 total project budget for complete turnkey installation.

### Long-Term Maintenance Costs

Educating customers on ownership costs supports realistic budgeting:

**Annual Requirements:**

– Exterior treatment inspection and touch-up: €150-350

– Gutters and drainage maintenance: €80-150

– Door/window adjustment and sealing: €100-200

– Structural inspection: €0-150 (DIY or professional)

**5-Year Cycle:**

– Complete exterior re-treatment: €800-1,800

– Roof inspection and repair: €300-800

– Glazing seal replacement: €200-500

**15-20 Year Expected:**

– Roof covering replacement: €2,500-6,000

– Window replacement: €3,000-8,000

– Major structural treatment: €1,500-4,000

Total ownership cost over 25 years typically equals 60-80% of initial purchase price, making log cabins highly cost-effective compared to conventional construction (100-150% additional costs).

## Phase 5: Timeline and Project Management

### Realistic Timeline Expectations

Setting accurate timeline expectations prevents dissatisfaction:

**Planning Phase (2-6 weeks):**

– Design selection and customization

– Site assessment and preparation planning

– Permit research and application

– Foundation specification and contractor selection

**Manufacturing (6-10 weeks standard, 12-16 weeks custom):**

– Production queue time

– Manufacturing and quality control

– Treatment and finishing

– Packaging and logistics preparation

**Site Preparation (1-4 weeks):**

– Site clearing and grading

– Foundation construction and curing

– Utility rough-in if required

– Material staging preparation

**Assembly (3-15 days depending on size/complexity):**

– Component unpacking and organization

– Wall construction and assembly

– Roof installation

– Window and door fitting

**Finishing (2-6 weeks):**

– Insulation installation

– Electrical and plumbing completion

– Interior finishing

– Exterior treatment and landscaping

Total timeline from order to completion: 14-28 weeks typical, 32-40 weeks for complex custom projects.

## Phase 6: Supplier Selection and Dealer Evaluation

### Quality Indicators for Customer Education

Equip customers to evaluate dealer credibility and product quality:

**Manufacturing Quality Signals:**

– FSC/PEFC timber certification (sustainable sourcing)

– Kiln-dried timber specification (prevents twisting/warping)

– CNC precision cutting (ensures proper fit and assembly)

– Quality control documentation

– Warranty terms (10+ years structural for quality manufacturers)

**Dealer Service Indicators:**

– In-person site visit offers

– Detailed written quotations with specifications

– Reference customer contacts

– After-sales support clarity

– Assembly service options or clear DIY guidance

**Documentation Completeness:**

– Detailed technical drawings

– Assembly instructions quality

– Material specifications list

– Maintenance guidelines

– Warranty terms and claims process

## Dealer Implementation: Converting Education to Sales

### Using This Framework in Sales Process

Successful dealers integrate customer education throughout the sales journey:

**Initial Consultation:** Use needs assessment framework to understand requirements before product presentation. Demonstrates expertise and builds trust.

**Proposal Development:** Present options within appropriate specification ranges based on needs analysis. Include total cost transparency using budget breakdown framework.

**Decision Support:** Provide this guide as value-added resource. Positions dealer as educational partner, not just product vendor.

**Post-Sale:** Use timeline framework to set expectations and maintain communication throughout project.

Dealers implementing comprehensive customer education frameworks report:

– 35-40% reduction in sales cycle length

– 25-30% increase in average transaction value

– 50-60% increase in referral rate

– 40-45% reduction in post-sale support calls

For the Eurodita dealer network, customer education represents a powerful competitive advantage, enabling premium positioning through demonstrated expertise and comprehensive support that extends far beyond basic product sales.

Request a B2B partnership quotation