CNC wood machining offers the ideal blend of precision and creativity to woodworking projects. Selecting an effective technique helps ensure optimal results while reducing material waste.

Selecting the proper machine, CAD software and cutting bits can have a dramatic impact on outcomes. Clamping and positioning workpieces properly to avoid unnecessary movement during machining is also key to producing consistent cuts; using appropriate tools will only enhance product quality further.

Accuracy

CNC timber cutting machines bring woodworking art to a whole new level, enabling craftsmen and manufacturers alike to craft unique designs with remarkable accuracy. Their advanced technology ensures precise execution of every cut – eliminating human error while simultaneously minimizing material waste – making mass production much less costly than before and guaranteeing flawless replication of design specifications across multiple batches.

CNC machinery also eliminates the need for extensive manual finishing, enabling you to achieve superior results in less time. Although many projects require fine finishes, manual finishing can be costly and time consuming – saving both money and effort while giving you more time and energy to focus on other areas of your business.

Effective CNC timber cutting requires careful planning in order to achieve optimal results. Take advantage of user-friendly CAD software to develop detailed designs, then test compatibility between your machine and wood type before beginning work. As different wood species require different machining conditions (hardwoods require precision while softwoods such as pine can be cut at slower speeds without burning surfaces), when planning your CNC timber cutting operation.

Selecting an optimal spindle speed and feed rate are crucial to producing clean cuts without damaging wood. Conducting practice runs with scrap pieces before beginning any actual projects will allow you to determine the optimal settings. Online forums or feed rate calculators may also assist with finding an equilibrium between performance and safety.

Laser cutters for wood are another highly accurate tool that use focused beams of light to vaporize material, producing precise cuts without needing abrasions and other damaging processes. Ideal for projects involving intricate patterns and textures, laser cutting eliminates these problems altogether.

Nested-based manufacturing is an efficient CNC timber cutting technique that maximizes material usage by stacking multiple design components on one sheet of wood. This process makes it possible to produce entire sets of furniture using just one piece of plywood, saving both time and money in production costs. Furthermore, using this technique makes cutting large wooden sheets much simpler thus improving productivity and efficiency.

Efficiency

Wood CNC machining enables users to produce timber parts without extensive manual labor, significantly decreasing production costs and improving efficiency. Its versatility also enables manufacturers to produce consistent dimensions and designs across their products, which makes this method particularly helpful in projects requiring precise woodworking skills such as furniture construction or decorative panels. Furthermore, this method can also be used on plastics or metals.

Selecting the Appropriate Types of Wood

Selecting the proper types of wood for your project can have a tremendous effect on its final result and quality. Oak and walnut are popular choices due to their durability; while softwoods like pine or cedar offer flexibility and cost effectiveness. Every wood species offers specific properties that work well under specific machining conditions.

Hardwoods require slower machining speeds in order to avoid burn marks on their surface, necessitating more powerful machines and perhaps additional safety precautions. On the other hand, softwoods tend to be lighter weight and easier to cut with reduced tool wear and maintenance costs.

Before commencing with any machining process, it is critical that the machine be set up appropriately in order to achieve accurate results. This includes setting up the workspace with dampening materials to minimize vibrations or other factors which might impede accuracy. Furthermore, selecting appropriate tools based on project specifications and wood type can prevent damages or wasteful spending.

Conducting a dry run prior to starting to use your tool can also identify any errors in programming or setup, saving both time and money by quickly identifying issues early. Utilizing sacrificial spoil boards on worktables to prevent damage while simultaneously absorbing any unexpected cuts or drill-throughs can also prevent unnecessary disruptions to production schedules.

Investment in a dust collection system is key for woodworking, as it will improve your working environment and safeguard you against health risks. A good system will collect excess dust and chips, keeping them out of the air where they could cause respiratory issues; in addition, it reduces damage risk on machinery while prolonging its lifespan and helping achieve higher quality outcomes.

Versatility

CNC technology empowers woodcutter to complete intricate projects quickly and without manual effort, eliminating human errors and guaranteeing timber parts are free from defects. Furthermore, Woodworking CNC also offers flexibility regarding production volume and material selection to meet client requirements and market demands.

Based on your requirements, CNC technology can be used to produce projects using various materials – steel and aluminum among them – using CNC milled lumber being its most popular application due to its versatility, efficiency, durability and affordability.

For optimal CNC performance, it is critical to understand the unique needs of every type of wood material. Softwoods such as pine are popular choices for prototyping and home decor items due to their soft nature, while hardwoods like oak and cedar provide increased strength and durability for higher traffic items. Furthermore, selecting appropriate cutting tools such as straight bits for smooth cuts while V-bits may be better suited for carving intricate details is equally crucial in order to use a CNC machine effectively.

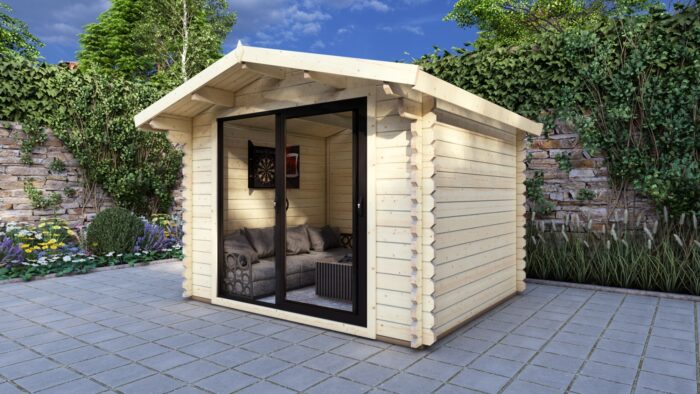

Woodworking CNC allows users to build decorative arts and wooden crafts such as picture frames, Christmas ornaments and plaques with its wide array of tools. Furthermore, it can also be used for more complex projects such as furniture manufacturing and architectural structures. Woodworking CNC machines can be customized with multi-axis machining systems to offer greater precision for curved surfaces. This advanced technique is especially helpful in architectural woodworking and custom furniture design where accurate curves are crucial components. Woodworking CNC technology can also assist in producing more precise results on artistic projects such as ornate chair frames and wooden columns, saving both time and labor by eliminating manual finishing processes – benefits especially valuable in today’s fast-paced woodworking industry.

Sustainability

CNC Cutting offers woodworkers an environmentally-friendly option to produce higher-quality outcomes while conserving materials. This is due to digital instructions being utilized, reducing human error and guaranteeing accurate cuts each and every time. Furthermore, it reduces waste production by eliminating unnecessary cuts.

Contract cutting services with automated CNC static table systems provide businesses with a cost-saving way of improving efficiency by eliminating manual labor and speeding up production times, saving both money and giving customers better results. Furthermore, using contract cutting services allows companies to scale operations while upholding quality standards.

An efficient work environment not only increases productivity but also ensures increased efficiency by reducing machine downtime and prolonging equipment lifespan. This is especially evident with CNC routers as dust collection systems help address mechanical issues caused by build-ups of debris accumulation; as such they play an essential role in making sure operations run smoothly and efficiently.

CNC woodworking has quickly become an essential tool in cabinetmaking. Used with advanced tools and woodworking techniques, these machines enable professionals and amateurs alike to achieve extraordinary results with minimal effort – including increased accuracy and precision, efficient resource usage and the creation of intricate designs.

Luxury property renovation project that utilized a rotary axis wood CNC machine to design custom storage solutions that seamlessly integrated with existing architectural elements and to maximize material usage by employing nesting techniques to reduce scrap. This demonstrated its versatility and power – this type of advanced machine could also be applied creative projects outside furniture construction.

Wood CNC machining systems can also be used to sculpt molds for other forms of material and create prototypes to test product designs before launch. Since these machines can cut and shape a variety of materials – such as metals – as well as making templates and jigs for woodworking, CNC is ideal for producing high-quality products that require complex shapes with precise geometry.