Wood is hygroscopic, meaning that its moisture absorption depends on its surrounding conditions. When exposed to high humidity levels, however, the material may expand and warp.

Low humidity levels can wreak havoc on wood furniture, flooring and structures made of wood, leading to cracking, deformations and shrinkage of these objects. To keep your wood in top shape: 1. Opt for moisture-resistant materials

1. Keep it dry

Most people understand the need to dry wood prior to using it as lumber, with this drying process extracting moisture and producing lumber that is dimensionally stable, machineable and accepting of glues and finishes. But did you know it also results in changes to its internal moisture content (MC)? Here lies where things can really become exciting!

Humidity levels tend to rise during summer, leading to wood items in homes to absorb moisture and expand as temperatures cool off and dry out, only for it to expel its stored up moisture by shrinking as soon as the air clears – this cycle can damage fine furniture by changing its appearance or creating gaps between wood panels or cabinetry.

Solid wood furniture and items should be stored in temperature-controlled environments with relative humidity levels between 35 percent to 45 percent to ensure their MC remains consistent, since wood constantly releases and absorbs moisture, so even minute variations in its moisture content could result in swelling and shrinkage that could eventually cause warping, twisting or cracking to occur.

When working with solid wood, it is wise to use a reliable moisture meter that will give an accurate and representative reading of its moisture content (MC). While different types of meters exist depending on factors like species, density and moisture distribution in your material, all will provide accurate MC readings; dielectric meters tend to work best for thinner boards like 4/4 lumber while conductance meters offer the most precise readings when used on thicker board stock.

As part of good wood care practices, it is a best practice to store all wood elements in a dry, climate-controlled space until assembly or installation. This will reduce acclimation processes while protecting against moisture loss due to storage. Stacking properly, using protective treatments and maintaining good ventilation are additional ways you can protect timber against moisture damage; by doing this you’ll ensure its long life ahead.

2. Keep it clean

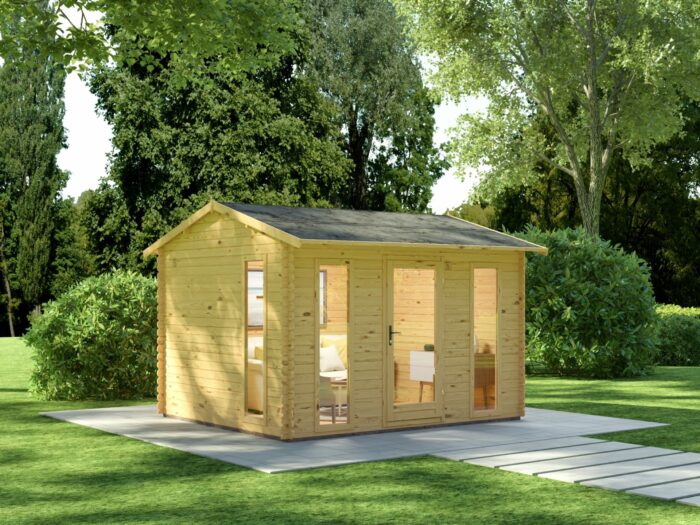

Wood is an extremely popular building material, known for adding warmth and beauty to homes or garden structures. Easy to access, durable and eco-friendly, it makes an attractive option when selecting material for building projects. However, as with any material it can become weather damaged over time; therefore wood structures must be treated carefully in order to preserve their beauty and functionality for as long as possible. Wood structures are particularly susceptible to moisture and UV damage so it’s crucial that appropriate precautions be taken when using them.

Maintaining wooden structures clean is one of the best ways to safeguard them against environmental forces, ensuring their longevity and reducing any chances of collapse or further deterioration. This requires regularly inspecting them for signs of wear and tear and taking swift action should any signs arise – this way any small areas of damage won’t worsen into bigger issues that threaten its integrity and could ultimately cause collapse.

Humidity can be detrimental to different kinds of wood, particularly if present for extended periods. It poses particular problems in homes composed mostly of wooden materials as humidity can cause it to expand and warp the material as well as corrosion metal components and weaken its structural integrity – all potentially dangerous consequences of excessive humidity in a building.

Moisture can accumulate behind walls and, left unchecked, lead to mold and mildew growth that if uncontrolled could affect air quality in the home as well as pose health concerns for inhabitants. Furthermore, insulation performance could also suffer significantly as this form of moisture could prevent its full performance potential.

Proper storage and moisture management are key to minimizing vapor pressure in wood and mass timber construction projects, and should always be prioritized over minimizing dimensional changes post installation. Acclimatizing wood to its work environment’s temperature and humidity before installing will help minimize any changes to dimensions once installation begins. Furthermore, data loggers or smart thermo-hygrometers can help monitor these factors to lower risks associated with moisture related issues in future projects.

3. Keep it oiled

Wood is an economical and quick to install outdoor structure option, making it popular among decking, cladding, sheds, and cabins. Wood provides an appealing natural aesthetic when assembled properly; however, humidity and insect attack pose two primary threats – these being visual damage as well as physical problems like warping, rot and mould/algae growth which reduce its life span over time. If left unaddressed they could lead to costly repairs or replacements down the line.

Wood is hygroscopic, meaning its moisture content (MC) fluctuates depending on the relative humidity in its environment. When its MC increases, wood expands; when its levels decrease, shrinkage occurs. A stable balance can be reached when wood meets equilibrium with surrounding air conditions – an outcome which can easily be predicted.

As temperature increases, moisture changes quickly. Therefore, selecting wood species known for being stable in your local climate is paramount to choosing suitable blanks for woodturning projects. Woodturners frequently saturate blanks with polyethylene glycol (PEG) to avoid hygroscopicity and minimize expansion or shrinkage in finished products.

Paint or varnish may help prevent moisture exchange between wood cells, yet still allow moisture to come in contact. However, oiling it regularly will ensure its longevity by replacing bound water in cell walls with pigmented oils that help stop dimensional change and keep wood looking new for years. Invest in quality product to extend its lifespan.

Before applying oil to an item of wood, always conduct an off-cut test first to make sure it is safe and effective. Furthermore, for best results it would be wise to use only one type of oil on items of similar types, since various oils will produce different finishes on wood surfaces.

As well as regularly cleaning your wood surfaces, other protective measures include installing dehumidifiers in indoor spaces with wood and using exhaust fans in kitchens and bathrooms. Furthermore, making sure it has enough ventilation without direct sunlight exposure will also help preserve its appearance and extend its lifespan.

4. Keep it dry

Wood can absorb a great deal of moisture, yet only retain certain levels. Drying wood to an appropriate moisture content is the best way to avoid damage caused by excessive moisture; woodworkers often employ techniques such as sunbathing and heating in winter or storing in greenhouses to achieve this end goal.

Hygrometers are useful tools for monitoring humidity levels and the moisture content in wood materials. An optimal range lies between 40 percent and 60 percent to allow moisture to pass into and out of wood without damage occurring to it.

Humidity levels tend to rise during summer, yet indoor relative humidity tends to decrease as water vapour evaporates from heated and dried-out air, due to water vapour loss. Any change in humidity over an extended period can result in major dimensional shifts; thus it’s crucial that wood become acquainted with its working conditions before dimensioning, gluing or joining to minimize changes and reduce dimensional shifts. Acclimating wood for at least a week before dimensioning, gluing or joining may reduce dimensional differences significantly and help prevent significant dimensional shifts caused by differences between humidities and environments can help minimize changes.

Moisture that remains trapped within wooden structures for too long can lead to decay and fungus growth, including rot and dry rot caused by specific species of fungi that do not require liquid water in order to thrive; they can even decompose completely dry wood structures.

To protect wood surfaces from rot, it’s essential that regular inspections take place for signs of decay. Check for soft areas with easily broken grain as well as any splinters to identify damaged areas and use epoxy coatings on wood to slow its rate, though not completely prevent its appearance.

By taking a few simple measures, end customers can protect and extend the lifespan of their wood surfaces in their home. From selecting moisture-resistant woods to installing ventilation systems and fans for humid spaces to maintaining gutters and drainage systems that help facilitate runoff while discouraging surface accumulation – proper wood maintenance will protect the property against moisture damage and fungal infestation.